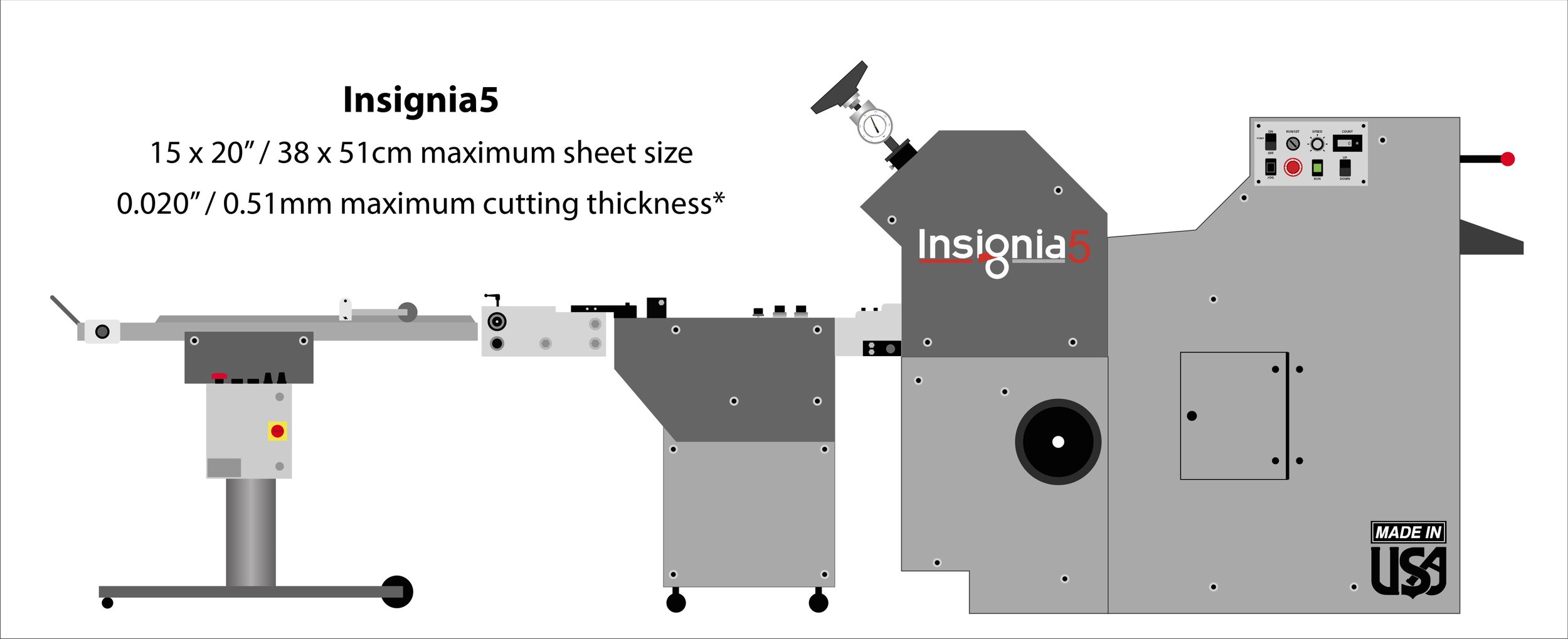

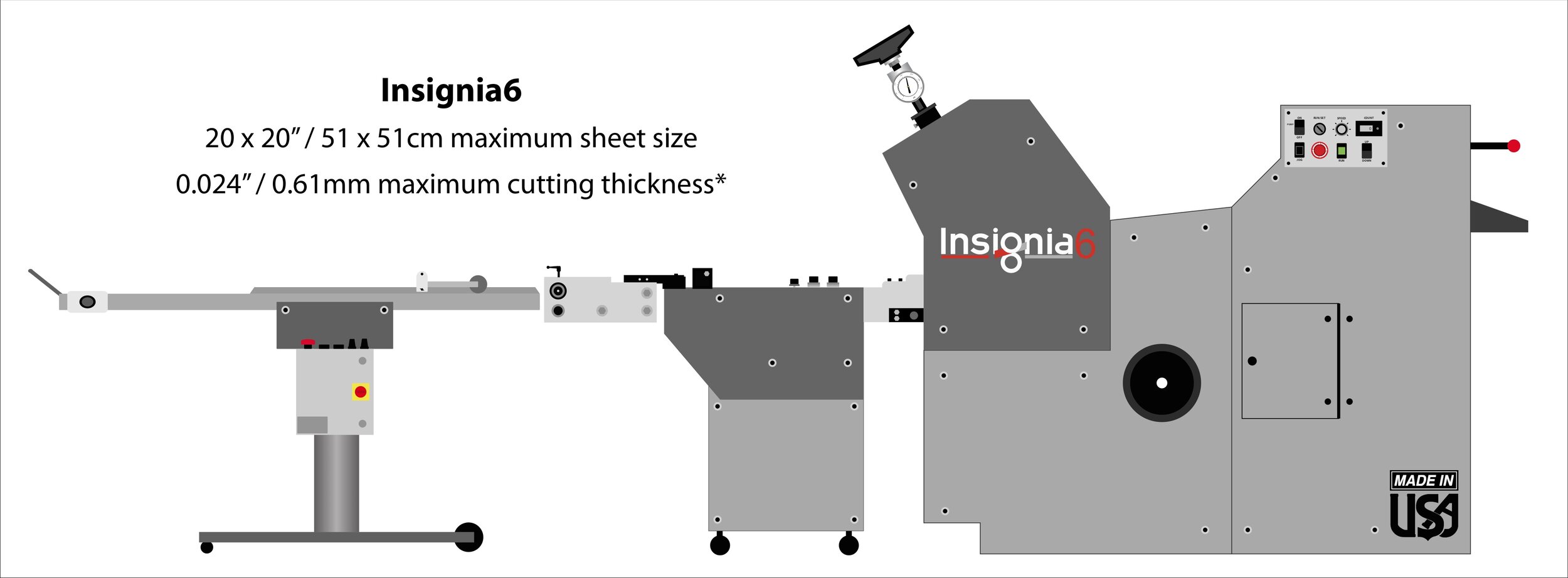

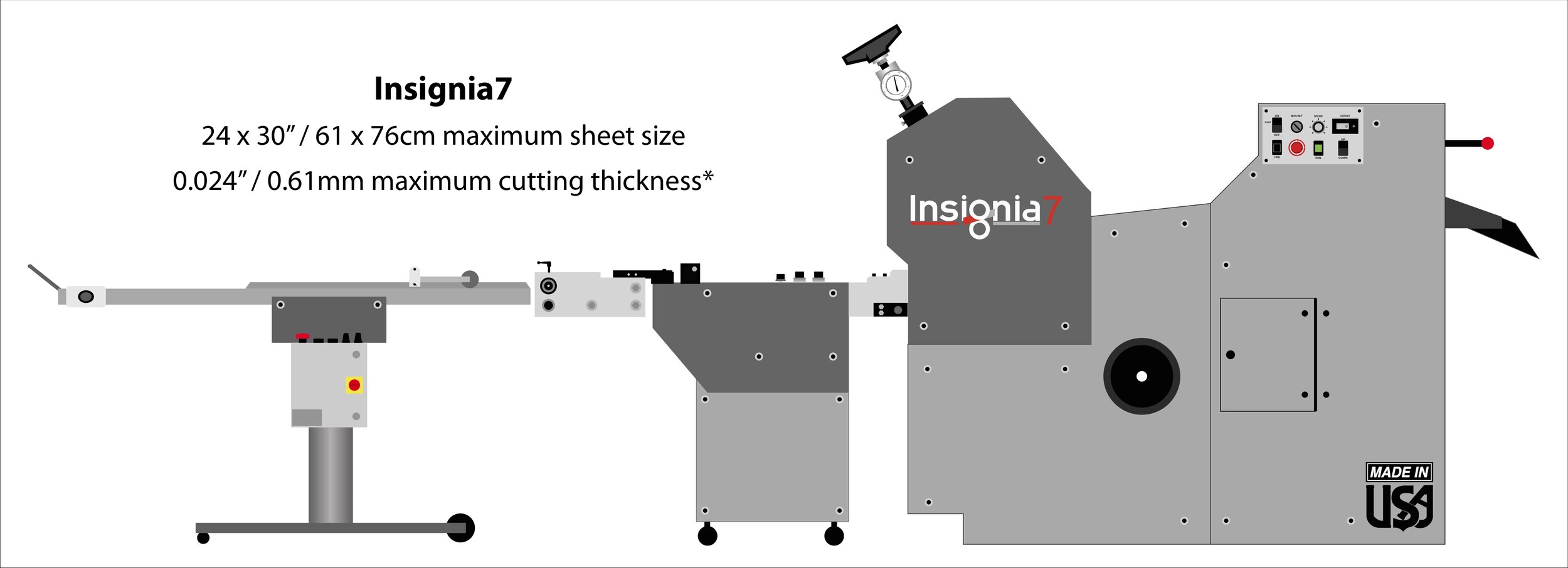

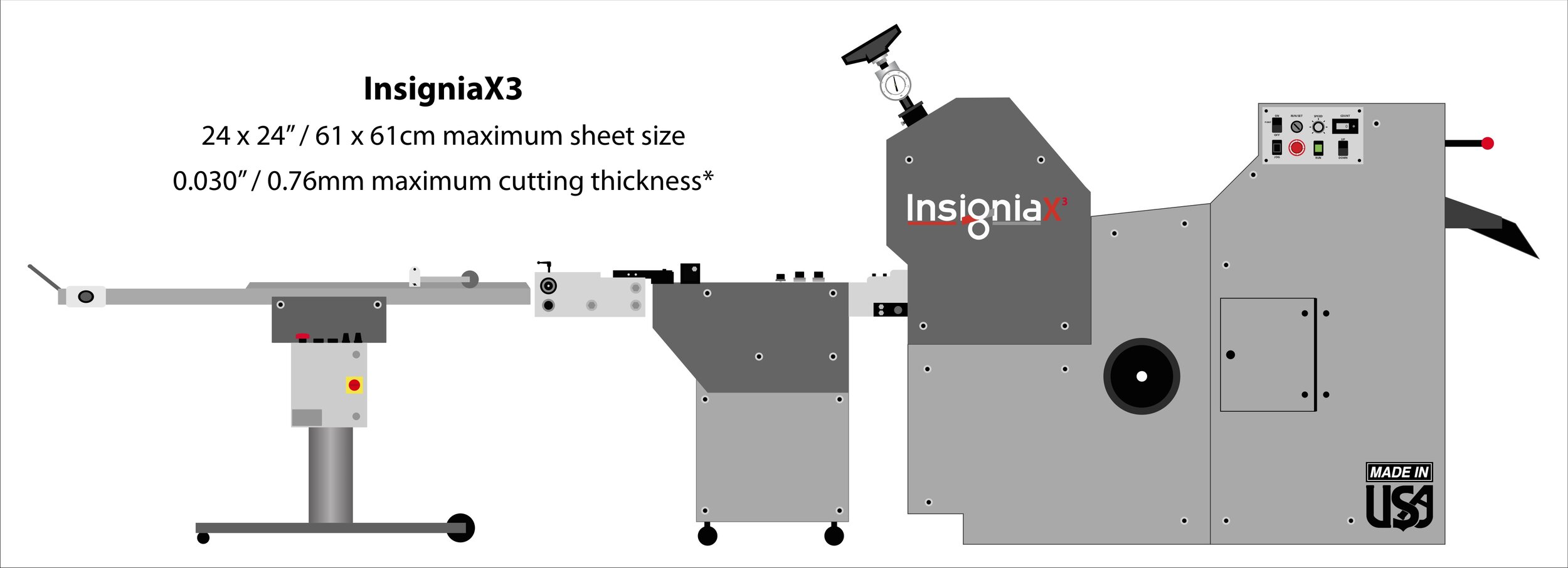

Insignia die cutters are offered in 4 sizes:

Production-grade Manufacturing:

Insignia machines weigh between 3,000 - 5,500lbs depending on size of machine (die cutting section only). The machines are built with 1.5-2.5" (38-64mm) thick solid side-frames to house the cylinder section and support the cutting station.

When die cutting materials of density, tremendous forces are required to withstand the pressures needed to die cut all the way through the substrate. This is why the Insignia machines are capable of applying up to 3,000lbs of downward force directly to the cutting station to ensure the flexible dies can cut through whatever it is being asked to do.

The Insignia machines are built 100% in the USA using American sourced components.

Shown above is an Insignia6 size machine producing 2up auto-lock folding cartons. Capable of being ran in-line to folding/gluing equipment for in-line production of folding cartons, presentation folders or packaging products utilizing a single operator.

Above is a flexible die tool being mounted on a single magnetic Insignia6 machine utilizing a recessed scribe line to ensure die is parallel on the cylinder, and then aligned to a center scribe.